Digital technology has transformed paint finish quality standards monitoring in auto body restoration and vehicle repair, leveraging tools like CAD software, 3D scanning, high-resolution imaging, and AI to ensure precise, consistent results. These advanced systems enable minute-by-minute tracking of painting progress, detect subtle imperfections, and minimize damaging processes, leading to better aesthetics and longer-lasting finishes. This benefits both workshops and consumers globally by fostering a culture of continuous improvement in paint finish quality standards.

Digital technology is transforming the landscape of paint finish quality standards monitoring. From initial application to final inspection, innovative tools are enhancing precision and efficiency. This article explores how digital solutions, such as advanced sensors, AI-driven analysis, and real-time data visualization, revolutionize quality control in paint finishing. By delving into these technologies, we uncover their impact on improving consistency, identifying defects early, and fostering continuous improvement in the painting industry, ultimately raising the bar for paint finish quality standards.

- Digital Technology: A New Tool for Quality Control in Paint Finishing

- Enhancing Precision and Efficiency: The Impact on Paint Finish Quality Standards

- Future Prospects: Continuous Improvement through Digital Innovation in Painting Processes

Digital Technology: A New Tool for Quality Control in Paint Finishing

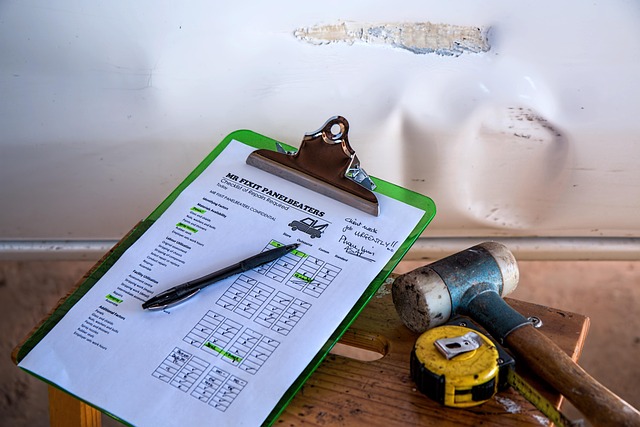

Digital technology has emerged as a game-changer in the realm of paint finish quality standards monitoring. It offers a robust toolkit for professionals in the auto body restoration and vehicle body repair sectors, enabling them to achieve precision and consistency in their work. By leveraging advanced digital tools, car repair services can streamline the inspection process, ensuring every paint job meets the highest standards.

This transformation is particularly evident in the way digital cameras and sensors capture intricate details of a vehicle’s surface, allowing for minute-by-minute tracking of the painting progress. Furthermore, software applications designed specifically for this purpose can identify imperfections, such as uneven colors or texture issues, that might be overlooked by the human eye. This not only enhances overall quality but also saves time and resources in the long run, making digital technology an indispensable asset for maintaining rigorous paint finish quality standards in auto body restoration and car repair services.

Enhancing Precision and Efficiency: The Impact on Paint Finish Quality Standards

The advent of digital technology has brought about a significant transformation in the realm of paint finish quality standards monitoring for automotive and vehicle applications. By leveraging advanced tools like computer-aided design (CAD) software, 3D scanning, and high-resolution imaging, professionals can now achieve unprecedented levels of precision during the auto painting process. These technologies enable detailed digital assessments, allowing technicians to detect even the subtlest variations in paint finish quality standards.

This enhanced precision translates into more efficient vehicle dent repair and removal processes. Digital systems facilitate real-time data capture and analysis, streamlining workflow and minimizing errors. As a result, final paint finishes are consistently of higher quality, meeting or exceeding industry benchmarks. This advancement not only benefits auto painting workshops but also ensures that vehicles undergo less damaging processes, contributing to better overall aesthetics and longer-lasting finishes—a win-win for both consumers and the industry at large.

Future Prospects: Continuous Improvement through Digital Innovation in Painting Processes

The future of paint finish quality standards monitoring lies in the continuous evolution of digital technology. As we move forward, innovative tools and techniques will play an increasingly vital role in enhancing precision and efficiency within painting processes, specifically in fields like collision repair and vehicle restoration. Advanced imaging technologies, such as high-resolution cameras and 3D scanning, can capture intricate details, enabling precise analysis and quality control.

Artificial intelligence (AI) and machine learning algorithms promise to revolutionize these processes by automatically detecting defects and variations, ensuring consistent paint finish quality. This digital transformation not only streamlines workflow but also fosters a culture of continuous improvement, where data-driven insights lead to more refined techniques, ultimately elevating the standards in car paint repair and vehicle restoration globally.

Digital technology has revolutionized paint finish quality standards monitoring, offering unprecedented precision and efficiency. By leveraging advanced tools and data analytics, industries can ensure consistent, high-quality finishes. As digital innovation continues to evolve, we can expect further enhancements in painting processes, ultimately driving continuous improvement in the standards of paint finishes across various sectors.