The integration of digital technology in automotive collision repair has revolutionized paint finish quality control, replacing traditional methods with real-time data analysis. Digital solutions enhance productivity through efficient inventory management, precise color matching, and streamlined communication, ensuring every vehicle meets the highest paint finish quality standards. Advanced sensors, robotic systems, and data analytics eliminate subjective human errors, resulting in consistently maintained or enhanced paint finish quality, increased customer satisfaction, and reduced rework costs.

Digital technology is revolutionizing the landscape of paint finish quality standards monitoring. This article explores how advanced tools and techniques are transforming traditional quality control processes. From high-resolution cameras and 3D scanning for meticulous inspection, to AI-driven software that identifies defects with unparalleled accuracy, digital solutions offer enhanced precision and efficiency. Real-time data management systems enable instant feedback loops, fostering continuous improvement and driving significant cost savings in manufacturing industries.

- Digital Technology: A Game-Changer in Paint Finish Quality Control

- – Exploring the benefits of digital tools for precise monitoring

- – Enhanced accuracy and efficiency through automation

Digital Technology: A Game-Changer in Paint Finish Quality Control

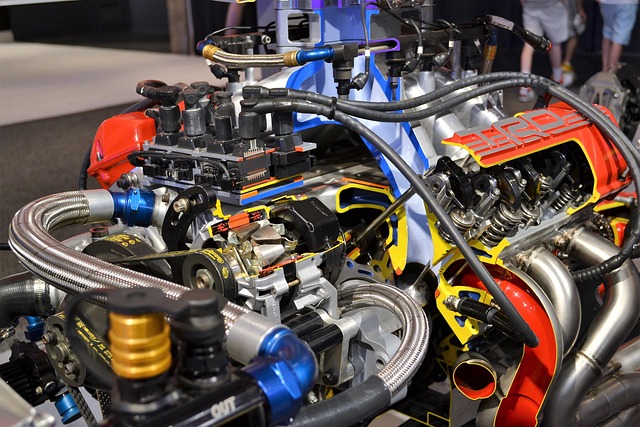

The integration of digital technology has revolutionized paint finish quality control in automotive collision repair and auto body shops, marking a significant departure from traditional methods. With precision and efficiency at its core, this innovative approach ensures that every vehicle leaving the repair shop meets the highest paint finish quality standards.

Digital solutions offer real-time data analysis, allowing professionals in vehicle repair services to identify defects swiftly and make immediate adjustments during the painting process. This level of precision is instrumental in eliminating imperfections, resulting in a flawless final product. Furthermore, digital technology enables efficient inventory management, facilitates precise color matching, and streamlines communication among shop personnel, thereby enhancing overall productivity in auto body shops.

– Exploring the benefits of digital tools for precise monitoring

The advent of digital technology has significantly revolutionized the way paint finish quality standards are monitored in various industries, particularly automotive sectors like bumper repair and auto detailing. Traditional methods often relied on manual inspections, which were time-consuming, subjective, and prone to human error. However, digital tools offer a new era of precision and efficiency. These innovative solutions, including high-resolution cameras, advanced sensors, and image analysis software, enable detailed visual examinations of paint finishes across different surfaces.

By integrating these digital capabilities into quality control processes, professionals in vehicle paint repair can achieve remarkable accuracy and consistency. Real-time data capture and analysis ensure that every nuance of the paint job is meticulously documented and compared against established standards. This level of precision not only enhances overall quality but also facilitates prompt identification and correction of any deviations, ensuring every finished product meets or exceeds expectations.

– Enhanced accuracy and efficiency through automation

Digital technology has revolutionized the way we monitor paint finish quality standards in industries like auto body painting and vehicle restoration. Automation plays a pivotal role in enhancing both accuracy and efficiency. By employing advanced sensors, robotic systems, and data analytics, digital tools can precisely measure color consistency, surface smoothness, and overall aesthetic appeal with remarkable speed and consistency.

This automation streamlines the inspection process, eliminating subjective human errors commonly found in manual assessments, especially during complex auto collision repair tasks. As a result, paint finish quality is consistently maintained or even improved, ensuring customer satisfaction and reducing rework costs for businesses in these industries.

In today’s digital era, technology has revolutionized paint finish quality standards monitoring, offering unprecedented precision and efficiency. By leveraging advanced digital tools, manufacturers can ensure consistent, high-quality outcomes, streamlining processes and reducing waste. This enhanced accuracy not only improves product consistency but also contributes to environmental sustainability by minimizing the impact of flawed finishes. As digital solutions continue to evolve, the future looks promising for maintaining and raising paint finish quality standards across industries.